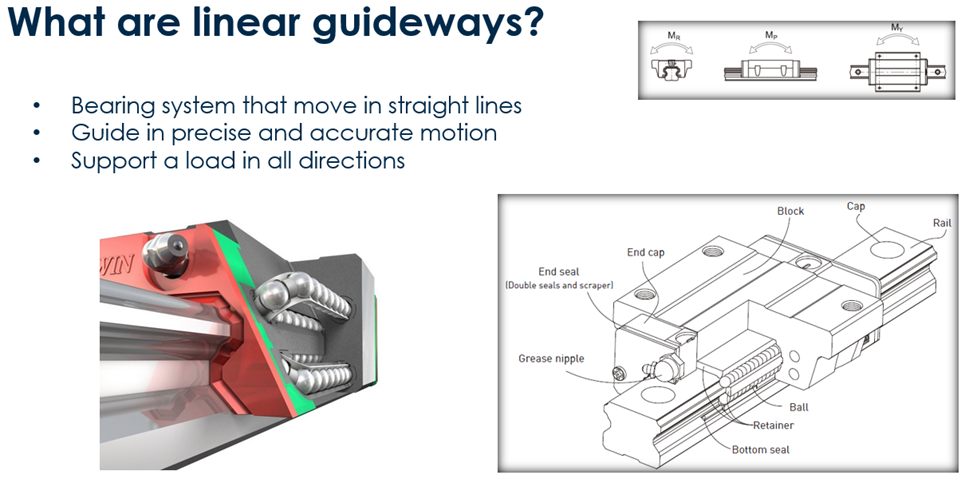

Linear bearings are crucial in various industries, allowing for precise and seamless linear motion. They are widely used in industrial machinery, automation systems, robotics, and other applications. They're are also called linear guideways. This article examines the fundamentals of linear guidance by means of bearings and rails.

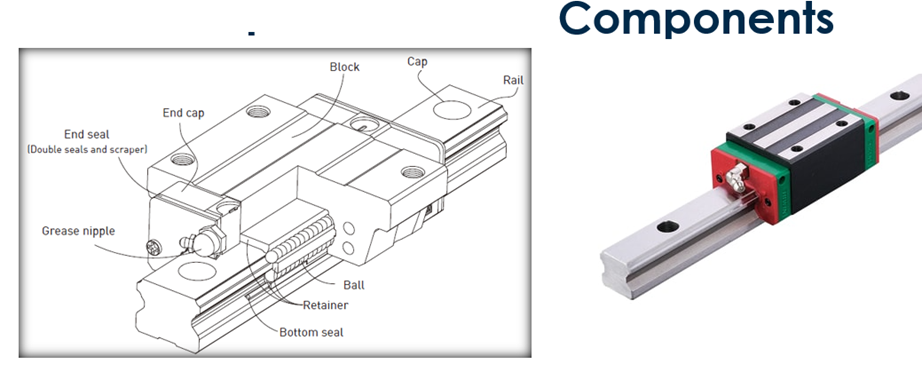

A linear guide, also referred to as a slide or bearing, is a mechanical component intended to facilitate linear motion with minimal friction and high precision. It comprises of two primary parts: a guide rail and a guide block. Linear guides support and guide the moving components, ensuring they move smoothly and precisely along a straight path

How do Linear Bearings Work ?

Ball bearings or rollers inside the block promote smooth motion along grooves present in the rail which is fixed, providing a rigid guide.

Bearing Block: The guiding block's rolling elements make contact with the guide rail. These rolling elements provide a smooth, low-friction path for the guide block as it is pushed or dragged along the guide rail. Reduced Friction Utilizing rolling elements significantly reduces friction between the guide block and guide rail. This friction reduction enables finer motion, greater efficiency, and less component wear and tear. The system's load capacity is determined by the size, shape, and quantity of the rolling elements, as well as the size and material of the guide rail and block. Typically, a more significant number or larger dimension of rolling elements can support a more substantial load.

Guide Rail: The fixed component of a linear guide system is a linear guide rail, also known as a track or a path. It provides the guide block with a precise linear way to travel along. Typically, guide rails are made of hardened steel or other materials with superior rigidity and abrasion resistance. They are available in various shapes, including square, round, and profiled rails, each suited for applications. The intended travel distance and system configuration determines the guide rail's length and mounting configuration.

Linear motion bearings are available in various configurations, each offering distinct advantages based on the specific application requirements.

The linear guideways of Hiwin, including the HG series, are constructed with a four-row circular contact design. This design permits bearings to accommodate stresses from all directions, making them highly versatile. They offer superior load capacity, high rigidity, and precise, dependable motion.

Types of Linear Bearings

a) Linear Ball Bearings: Linear Ball Bearings Hiwin offers highly efficient linear ball bearings that reduce friction for seamless motion. They are optimal for applications requiring moderate load capacity and high precision.

b) Linear Roller Bearings: Linear Roller Bearings The load-carrying capacity and rigidity of Hiwin's linear roller bearings make them ideal for heavy-duty applications.

Seal Kits – Extra protection against foreign substances entering the bearing internal cavity, which could compromise its performance and life

Scraper Kits – These act as robust shields protecting the bearing in dirty or abrasive environments; they actively clear the rail during travel moving any objectional debris from its path

E2 Lubrication Kits – Significantly reduce maintenance intervals by dispensing lubrication to the bearing during travel via a small oil reservoir.

Advantages of Linear Bearings

● Precision: Hiwin Linear Bearings offer high precision, enabling precise linear motion.

● Load Capacity: Due to their superior design, Hiwin's bearings can accommodate burdens from multiple directions, significantly boosting their load capacity.

● Rigidity: The circular four-row design of Hiwin's linear guideways provides increased rigidity, making them suitable for heavy-duty applications.

● Self-Lubricating: Certain Hiwin Linear Bearings have self-lubricating packages that reduce maintenance needs and increase bearing life.

● Versatility: Hiwin provides a vast selection of linear bearings suitable for various applications, ranging from small electronic devices to large industrial machinery.

● Noise Reduction: Linear bearings can also contribute to the quieter operation of machinery. Since they generate less friction and vibration, they typically generate less operational noise than other bearing varieties.

● Efficiency: Their design allows linear bearings to operate at high speeds with minimal energy loss. It makes them a viable option for numerous motion control systems.

Overall, Hiwin is renowned for its products' quality and optimal performance under demanding industrial conditions. Their extensive selection of linear bearings suits various applications and meets varying precision, load capacity, and maintenance requirements.

Hiwin Linear Bearings play a vital role in achieving efficient power utilization, and Hiwin is a renowned leader in this field. As the largest distributor of Hiwin products in Canada, Proax takes pride in offering their cutting-edge linear bearings.

Looking to enhance productivity while conserving energy? Let's have a conversation! We are eager to assist you in selecting the perfect Hiwin linear bearing that suits your requirements. Get in touch with us today, and together, let's empower a sustainable future with Hiwin Linear Bearings.